automatic capsule filling machine working principle

Tamping Pin Type Capsule Filling Machine Working Principle Capsule Filling Machine SaintyCo manufactures all types of capsule filling machines including tamping pin capsule filling machine automatic capsule filling machine semi-automatic capsule filler and more. Automatic Capsule Filling Machine Working Principle Ipharmachine Academiaedu is a platform for academics to share research papers.

Automatic Capsule Filling Machine Manufacturer Upmach

The positioning of colourless translucent capsules in the capsule filling tray.

. Pharmaceutical processing is a series of steps and capsule filling is an important part of the process. The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork one by one. A fully automatic capsule filling machine is an electromechanical system that fills either hard or soft gelatin capsules with appropriate materials or substances.

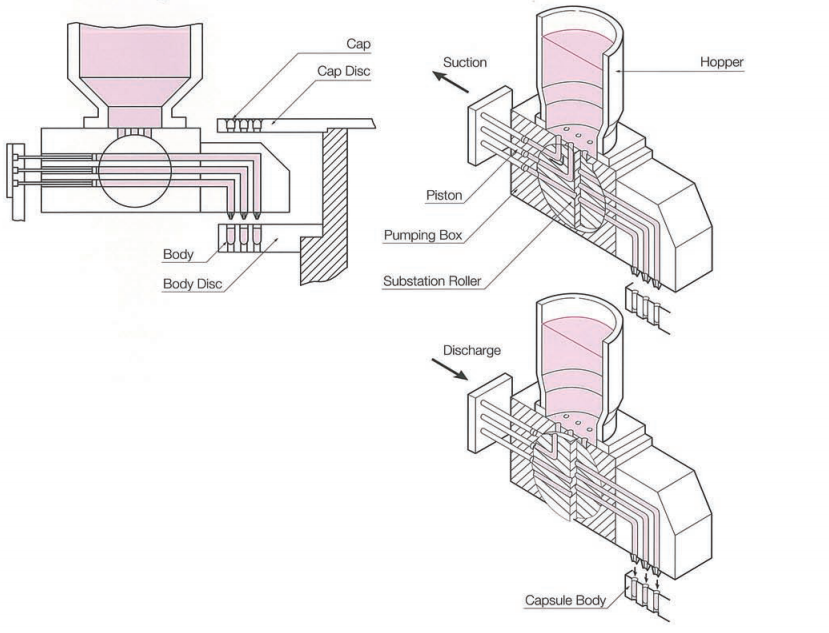

The product adopts plug filling intermittent operation frequency conversion and speed regulation. The tablets are put into the capsules. The Working Principle of SaintyCo Dosator Capsule Filling Machine A dosator machine may have two segments.

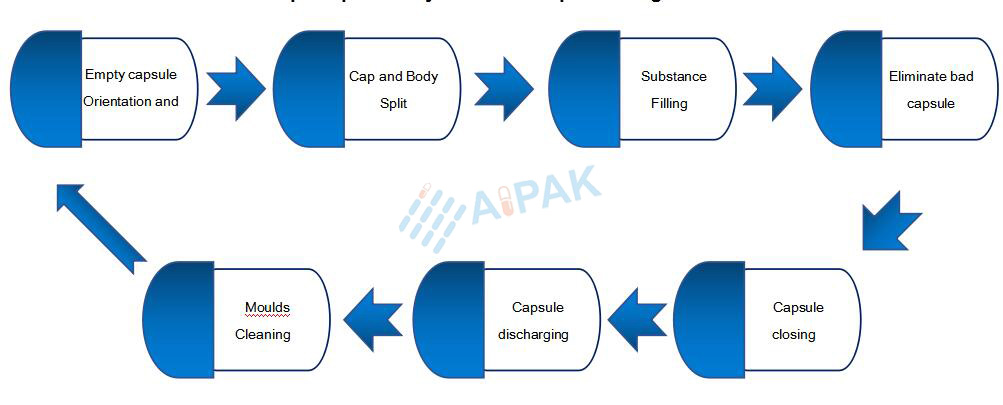

Injection wedge for automatic capsule fillers for instance may come with sensors to help coordinate motion. The capsule filling machine works in a step-by-step process that is as mentioned below. Continue reading Capsule Filling.

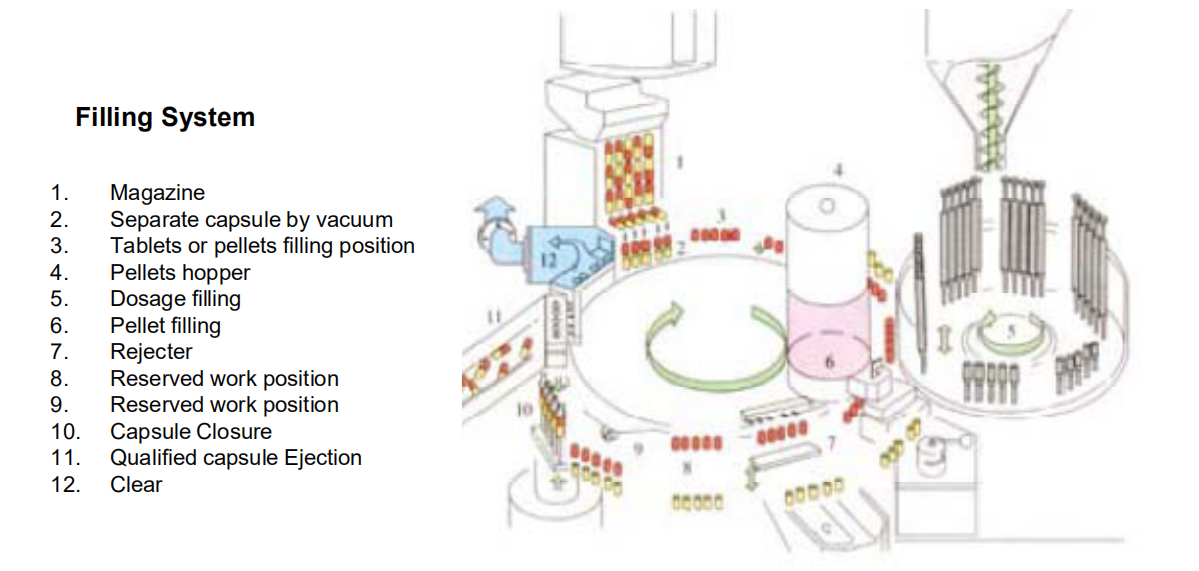

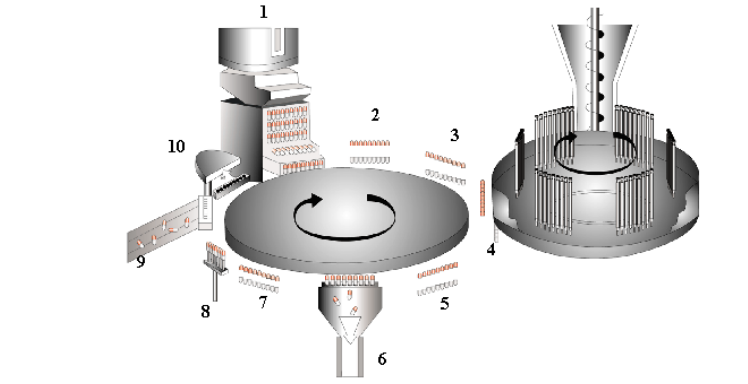

The Working Principle Of Automatic Capsule Filling Machine May 12 2021 1capsule movement During the intermittent capsule filling machine the movement of the capsule is dependent on the partition box for continuous dis continuous rotation The filling volume of the capsule is mainly determined by the volume of the measuring disc hole. Working Principle of Capsule Filling Machine 1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by the push rod through the capsule tank. We will power on the machine by pressing the start button for the machine to commence operation.

The digital liquid filling machine works on a stable electricity supply sometimes automatically adjusts itself withlow power supply under certain scenarios. You can also look for the best pill filler through. As you will see later in this guide the type of material here may include powder pellets suspension liquid etc.

Senieer FBM Series fluid bed processor working principle offers the possibility to dry granulate or coat particles in a single machine. We should also key in the major operation parameters at the PLC control system to guide the operations of the machine. It has 9 holes turning out a highest output of 1200 capsulesminute.

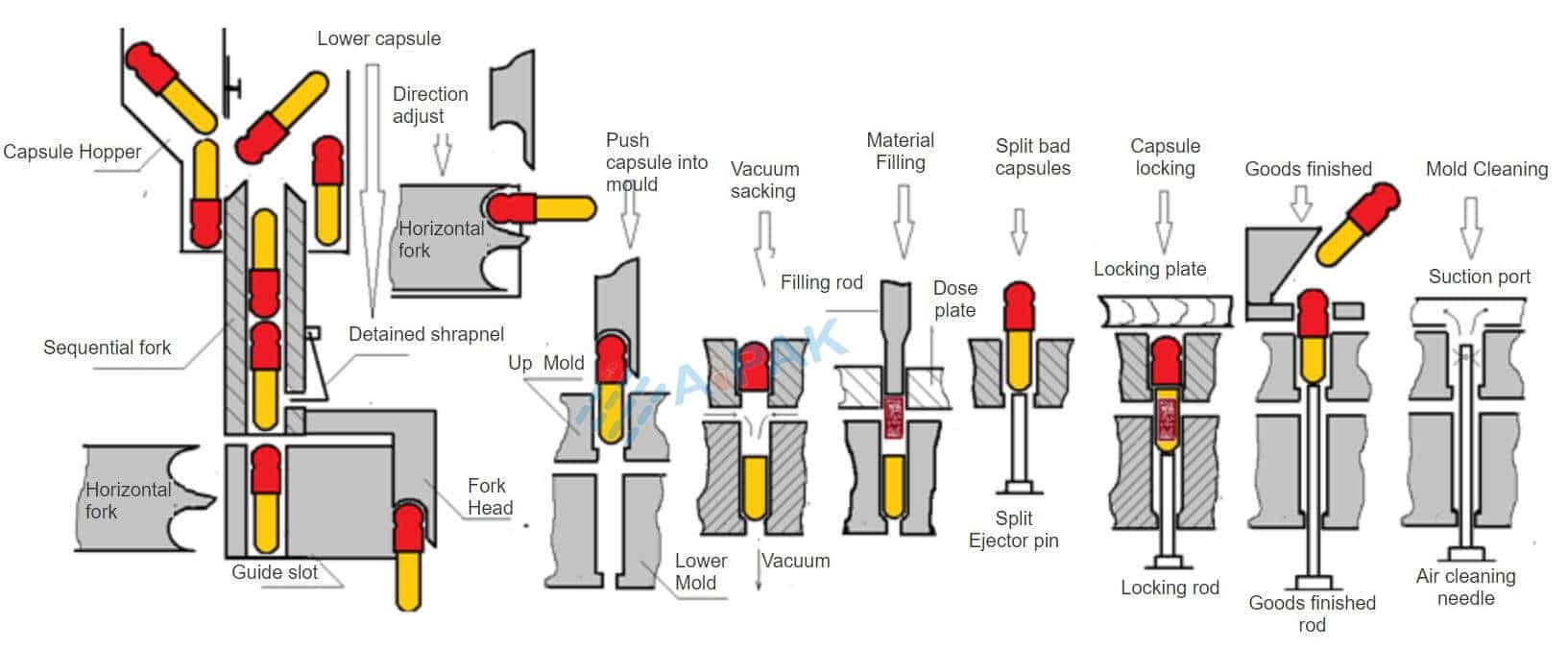

The tablets are pushed into the capsule through the feed pipe. Dosing of fill materialformulation filling the bodies. First the capsule caps are divided from their bodies.

The dosing revolving process is as below. After that the material is filled in the capsules with the help of powdergranule filler present in the capsule filler machine then the caps and body are rearranged in the machine itself. Aipak Automatic Capsule Filler Machine Details Introduction 1Automatic Capsule Filler Machine Working Principle 2Automatic Capsule Filler Station 3Upper Mold Movement 4Double Shaft Double Oil Sealing 5Loading Valve 6Aviation Material 7Mold No.

Major principles of vial filling machine. The system is such that the powder bed is on one side while the empty capsule body is on the opposite side. The capsules in the holes are sent to each working station along with the intermittent rotation of the turn table.

The capsule filling machine work on certain principles. This machine is a device for filling powder granules or small pieces into hollow capsules. Filling up the capsule body with pharmaceutical ingredients Rearrange the caps and bodies Expulsion of filled capsules from the machine.

At the 1 st 2 nd station the vacuum system separates the capsules in position. Capsules must be properly processed and filled with capsule filler prior to shipment. It is suitable for the automatic completion of the broadcasting of powder or pellet medicines.

Rectification orientation of the bad gelatin capsules. When the fork is sent down six capsules are delivered at a. Some also come with shut off vales while others can move up and down.

After that we will load the empty capsules and the filling material into respective product hoppers. Most automatic capsule filling machines can fill capsule of different sizes by changing mold. The principles of the machines are as follows.

The capsules are rectified caps and bodies are separated active pharmaceutical ingredients API is filled wasted capsules are rejected capsules are locked in place ejaculated and then cleaned and all this done with the help of a capsule filler. Filling procedure is monitored by a sensor which detects the existence of tablets in the capsule. Material in hard gelatin capsules.

Filling structure is handled by modularity as well as precious design reliability and low wear and tear. In this station the upper and lower parts of the capsule body are separated by vacuum suction. With the function of auto detection when insufficient powderinsufficient capsules optional function and malfunction happens.

Separation of capsule caps from bodies. Our capsule filling machine can manufacture capsule size vary from size 00 0-4. 8Dry Vacuum Pump 9Safety 10Specific Details 11Capsule Filling Complete Process.

The machine can alarm and stop running automatically. Working Principle NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole. Machine Body The body is the most important part of a Capsule Filler as it determines the entire structures stability and durability.

Division of capsule caps from their bodies. Specifically we provide high-throughput topical formulation screening and. Operating principles of a capsule filling machine Capsule filling machines should all have the following operating principles in common.

A dosator machine with two. The device can be used for filling 1-3 round tablets with straight diameter into one capsule. The horizontal fingers rectify the direction of capsules and vertical fingers push the capsules into hole of segment with all caps on the up position.

These digital fillers scan if any error is occurred in bottles and pouches before reaching to the finalization of the product. This can be done manually or with the help of an automatic capsule filling machine. Separation of capsule caps from bodies The capsule tray is transferred to the capsule separation station and the vacuum divider raises to make its upper surface close to the lower surface of the lower segment without gap.

Rejoining of caps and bodies Ejection of filled capsules.

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd

Preparation Equipment Working Principle Animation Hunan Grand Packaging Co Ltd

Used Acg Pam Af90t Capsule Filling Line Youtube

How Different Types Of Capsule Filling Machine Work By Lodhapharma Issuu

Automatic Capsule Filling Machine Working Principle Ipharmachine

How Different Types Of Capsule Filling Machine Work

Njp 800 Automatic Pill Hard Capsule Filling Machine Capsule Making Machine China Capsule Filling Machine Manual Capsule Filling Machine Made In China Com

Capsule Filling Machine The Blueprint Guide Saintyco

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Semi Automatic Capsule Filling And Packaging Machine Cgn 208 D Riempitrice New Type Manual China Capsule Filling Machine Manual Made In China Com

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Semi Automatic Capsule Filling Machine Saintytec

Encapsulators Operating Principles Types And Sequence Of Events

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd